When the

refrigeration system breaks down, it is generally impossible to directly see where the fault occurred, and it is impossible to decompose and dissect the components of the

refrigeration system one by one. It can only be checked from the appearance to find out the abnormal phenomena in operation and make a comprehensive analysis. In the inspection, we usually know the running state of the system by watching, listening and touching. When the operating pressure and temperature of the system are beyond the normal range, there will be problems except for the deterioration of indoor and outdoor environment temperature, which is an important basis for judging the fault root.

1. Detection of pressure and temperature of refrigeration system

(1) pressure concept of refrigeration system: the refrigeration system can be divided into high pressure and low pressure during operation. The high pressure section from the exhaust port of compressor to the front of throttle valve is called evaporation pressure. The suction pressure of compressor is called suction pressure, which is close to evaporation pressure, and the difference between them is the flow resistance of pipeline.

For convenience, the evaporation pressure and condensation pressure of the refrigeration system are detected at the suction and exhaust ports of the compressor. I.e., suction and discharge pressures commonly referred to as compressors. The purpose of detecting the suction and exhaust pressure of the refrigeration system is to obtain the evaporation temperature and condensation temperature of the refrigeration system, so as to obtain the operating condition of the

refrigeration system.

(2) The concept of temperature in

refrigeration system: the temperature in refrigeration system covers a wide range, including evaporation temperature te, suction temperature ts, condensation temperature, exhaust temperature, etc. Evaporation temperature te and condensation temperature tc play a decisive role in the operating conditions of

refrigeration system.

A. evaporation temperature te: refers to the temperature at which the liquid refrigerant boils and gasifies in the evaporator.

B. condensation temperature tc: it is the temperature at which the superheated vapor of refrigerant condenses into liquid after releasing heat in the condenser. The condensation temperature can not be detected directly, only by detecting its corresponding condensation pressure, and then by consulting the refrigerant thermodynamic property table. When the condensing temperature is high, the condensing pressure rises relatively, and they correspond to each other. The condensing temperature is too high, the unit load is heavy, the motor is overloaded, which is unfavorable to the operation, and the cooling capacity decreases correspondingly and the power consumption increases, which should be avoided as far as possible.

C. exhaust temperature td: it refers to the temperature of the compressor exhaust port (including the temperature of the exhaust port connecting pipe). a temperature measuring device is required to detect the exhaust temperature, but a minicomputer is generally not set up. the temporary measurement can be detected by a semiconductor point thermometer, but the error is large. The exhaust temperature is affected by the suction temperature and condensation temperature, and the suction temperature or condensation temperature rises, so it is necessary to control the suction temperature and condensation temperature to stabilize the exhaust temperature.

D. Suction temperature ts: refers to the gas temperature of the compressor suction connection pipe. A temperature measuring device is required to detect the suction temperature. Generally, small units are not equipped with a temperature measuring device, which is generally estimated by hand touch during maintenance and debugging. It is generally required to control the suction temperature of

air-conditioning units to about 15℃. Exceeding this value has certain influence on the refrigeration effect.

2. Influence of suction pressure change on refrigeration system

When the refrigeration system is running, its suction pressure is closely related to evaporation temperature and refrigerant flow rate. For the system with expansion valve, suction pressure is related to the opening degree of expansion valve, refrigerant charge, cooling efficiency of compressor and load. In capillary system, suction pressure is related to condensation pressure, refrigeration capacity, compressor refrigeration efficiency and load. Therefore, when checking the refrigeration system, a pressure gauge should be installed on the suction pipe. Detection of suction pressure plays an important role in fault analysis.

(1) Factors of low suction pressure: the suction pressure is lower than the normal value, and its factors include insufficient

cooling capacity, small cooling load, small opening of expansion valve, low condensing pressure (referring to capillary system), and unsmooth filter.

(2) Factors of high suction pressure: suction pressure is higher than normal value, and its factors include excessive refrigerant, heavy refrigeration load, large opening degree of expansion valve, high condensing pressure (capillary system) and poor compressor efficiency.

3. Influence of exhaust (condensing) pressure change on refrigeration system

When the refrigeration system is running, its exhaust pressure corresponds to the condensing temperature, and the condensing temperature is related to the flow and temperature of its cooling medium, refrigerant inflow and cooling load. When checking the refrigeration system, an exhaust pressure gauge should be installed at the exhaust pipe to detect the exhaust pressure as fault analysis data.

(1) Factors of high exhaust pressure: When the exhaust pressure is higher than normal, there are usually small flow rate of cooling medium or high temperature of cooling medium, excessive refrigerant charge, large cooling load and large expansion opening, etc.

The above factors will cause the circulation flow of the system to increase, and the condensation heat load will also increase accordingly. Because the heat can't be dissipated completely in time, the condensation temperature rises, but the exhaust (condensation) pressure rises. When the cooling medium flow rate is low or the cooling medium temperature is high, the heat dissipation efficiency of the condenser decreases and the condensing temperature increases. When the cooling medium flow rate is low or the cooling medium temperature is high, the heat dissipation efficiency of the condenser decreases and the condensing temperature increases. For the reason of excessive refrigerant charge, the excess refrigerant liquid occupies a part of the condensing tube, which reduces the condensing area and causes the condensing temperature to rise.

(2) Factors of low exhaust pressure: the exhaust pressure is lower than the normal value, and its factors include low compressor efficiency, insufficient refrigerant amount, small cooling load, small opening of expansion valve, unsmooth filter, including low temperature of expansion valve filter screen and cooling medium.

The above factors will cause the cooling flow of the system to drop, the condensing load to be small, and the condensing temperature to drop.

According to the changes of suction pressure, exhaust pressure and exhaust pressure mentioned above, they are closely related. Under normal circumstances, the suction pressure rises and the exhaust pressure rises accordingly; When the suction pressure drops, the exhaust pressure drops accordingly. The general situation of exhaust pressure can also be estimated from the change of suction pressure gauge.

4. The relationship between intake temperature and exhaust temperature

Actually, the exhaust temperature of the system is closely related to the intake temperature. When the suction temperature rises, the exhaust temperature also rises relatively, and vice versa. If we understand their relationship, we can master and control them well and make the refrigeration system run better.

5. The influence of temperature change of compression condensing unit on refrigeration system

All the relevant temperatures of the unit components have a normal temperature range, which is an abnormal state. These abnormal factors may be faults or incorrect adjustments, but the reasons should be analyzed and handled or checked in time. These temperature points are difficult to be measured by thermometer, and can only be estimated by hand feeling, and then whether they are normal or not can be judged.

(1) Influence of exhaust temperature: in summer, the exhaust temperature of compressor is relatively high and cannot be touched by hand. According to the national standard, the exhaust temperature of R22 refrigeration system should not exceed 150 OC, which is abnormal. The reason of high exhaust temperature is the high suction temperature of compressor or the high condensation temperature, which must be paid attention to. The exhaust temperature is too low, and it is not too hot to touch the exhaust pipe by hand, which indicates that the suction temperature is extremely low, and the compressor may run in wet stroke or the operating state of the system with relatively little working medium. The wet stroke of compressor is easy to damage the valve structure; Running with very little refrigerant will affect the heat dissipation of motor windings and accelerate the aging of insulation materials.

(2) The influence of casing temperature change on compressor and refrigeration system: the temperature field on the outer surface of the totally enclosed reciprocating piston compressor casing can be divided into two parts: a. The upper casing is affected by the suction steam, and its temperature is relatively low, which is in a slightly hot or slightly cool range, estimated at about 30℃, and dew condensation may occur on the local casing surface around the suction pipe. B. The calorific value of the motor in the lower casing and the frictional heat brought out by refrigerant oil are mainly brought out of the casing by steam.

A. the influence and reason of high casing temperature: the casing surface temperature exceeds the normal range, mainly because the suction temperature of the refrigeration system is too high (higher than 15℃). Excessive hot steam enters the compressor and absorbs the heat in the casing, which makes the temperature of the steam higher, thus increasing the temperature of the casing. The temperature of superheated steam rises very high, and the temperature of the casing also rises very high, which is unfavorable to the cooling of oil, which will affect the lubrication of moving parts, accelerate the wear, and in serious cases, make the bearing hold the shaft (bite). In addition, it will cause the exhaust temperature to rise.

B. Influence and reasons of low casing temperature: the casing surface temperature is lower than the normal range, and the reason is that the suction temperature is too low (lower than 15℃). It is beneficial to the cooling of refrigerant oil and motor winding, but the refrigerating capacity decreases. When the suction temperature is extremely low, most of the casings will be condensed, and there is a danger of liquid strike, which is a fatal blow to the compressor, and special attention should be paid to it. At the same time, a large amount of refrigerant is dissolved in the refrigerant oil, which is not conducive to the lubrication of moving parts.

(3) Temperature condition of condenser

A. temperature condition of condenser: normally, the front half radiator pipe is very hot, and its temperature has a balance of slow and gradual decline. Compared with the first half, the heat sensitivity of the second half of the radiator tube is greatly reduced, because the refrigerant in the second half of the tube has gradually liquefied, reaching the condensing temperature and supercooling temperature. When abnormal conditions occur, one is that the first half is not too hot and the second half is close to normal temperature (ambient temperature), which is due to the compressor absorbing wet steam refrigerant or insufficient refrigerant amount. The other is that the whole condenser pipe is very hot, which is caused by too much refrigerant or small ventilation, or high ambient temperature.

B.

Water-cooled condenser: The shell of shell-and-tube condenser is normally hotter in the upper half and warmer in the lower half. Under abnormal conditions, the whole shell is not too hot, and the reason is that the amount of refrigerant is not enough. Another situation is that the whole shell is very hot, which is caused by insufficient cooling water or poor heat dissipation effect (scaling in water pipes). Under normal circumstances, the casing of the casing condenser is very hot, which is due to the small amount of cooling water or poor heat dissipation effect; Another reason is that the outer surface of the whole casing is not too hot, which is due to insufficient refrigerant amount.

(4) Temperature condition of the liquid reservoir: Under normal circumstances, the suction pipe feels very cold when touched by hand and has dew. The reason is poor heat dissipation of condenser, high condensing temperature or excessive refrigerant charge.

(5) Temperature condition of liquid pipe: under normal circumstances, the liquid pipe is warm. Under abnormal conditions, the liquid pipe is hot. The reason is poor heat dissipation of condenser, high condensing temperature or excessive refrigerant flow.

(6) Temperature condition of filter: the basic condition is the same as that of infusion tube, but it has a prominent abnormal phenomenon, that is, the filter may get cold. The reason is that the filter screen hole is blocked by sludge, which makes the filter unsmooth. When the refrigerant flows through the filter screen, throttling occurs, that is, some liquid evaporates and absorbs heat, which makes the filter get cold and seriously causes condensation. Another abnormal phenomenon is that the filter is not hot, which is equivalent to the ambient temperature. The reason is that the filter screen is completely blocked and the refrigerant cannot flow.

(8) When the temperature of the suction pipe is normal, the suction pipe feels very cool when touched by hand and has dew. Under abnormal conditions, first, the suction pipe is cold and there is too much dew, which causes the casing to condense in a large area. The reason is that the refrigerant flow rate is too large, and the liquid cannot be completely vaporized in the evaporator, so there is a phenomenon of liquid backflow. Its harmfulness is that the compressor may run in wet stroke, and in severe cases, liquid hammer will occur, and the valve plate will be threatened. Second, the suction pipe is not cool, does not condense, and the casing is very hot. The reason is that the refrigerant flow is too small or the amount of refrigerant is insufficient. As a result, the exhaust temperature rises and the refrigerating capacity decreases.

Water source rooftop chiller unit part in HAVC

Water source rooftop chiller unit part in HAVC

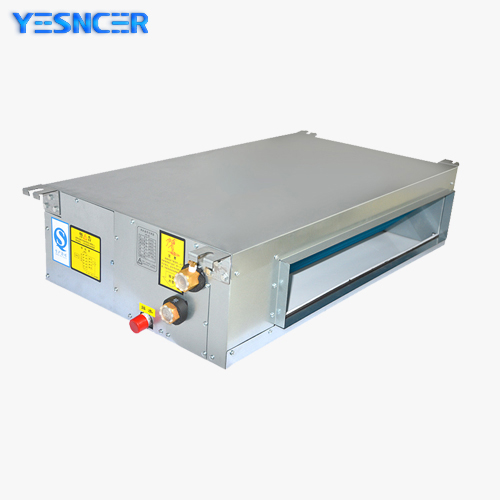

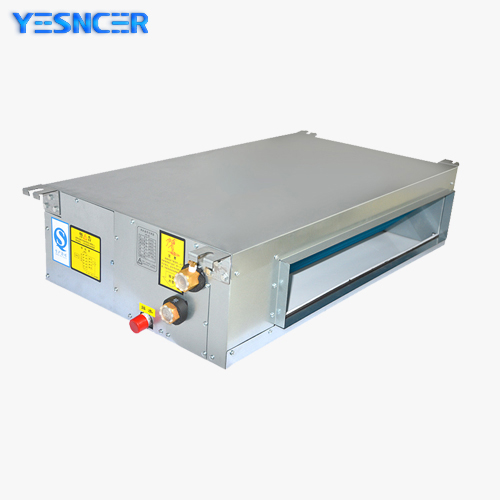

The quietness and efficiency of Guqin series Horizontal Ultra-Thin Concealed fan coil units

The quietness and efficiency of Guqin series Horizontal Ultra-Thin Concealed fan coil units

Ultra-low temperature air source heat pump principle and core technology

Ultra-low temperature air source heat pump principle and core technology

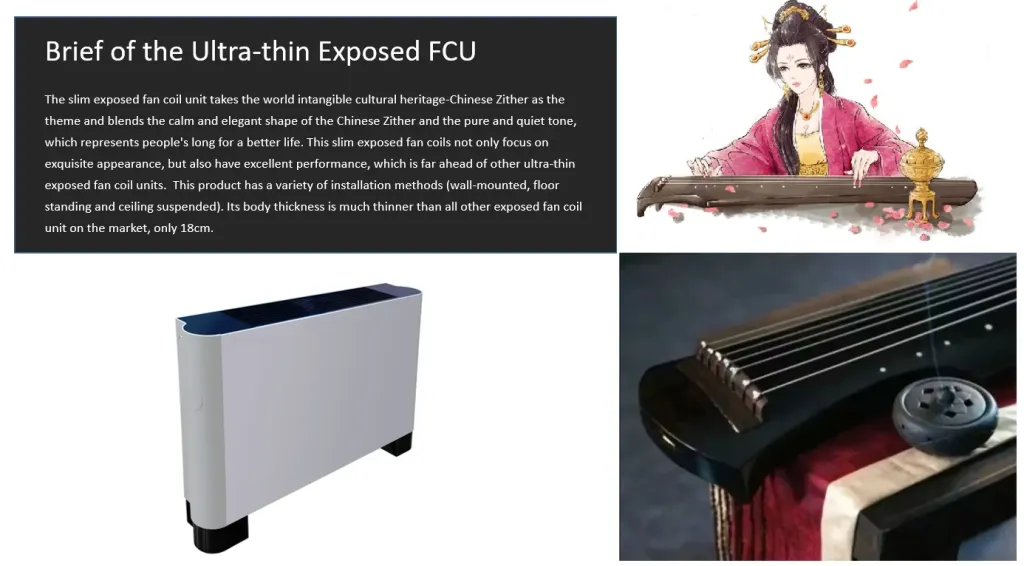

Fan Coil Unit Selection And Product Advantages

Fan Coil Unit Selection And Product Advantages