| instrument | Test pollutants | principle | measuring range | precision |

| SO2analyzer | So2 H2S | Pulsed ultraviolet fluorescence method | 0~2000x10-9 | 0.5x10-9 |

| NH3analyzer | NO2 NO NH3 | Chemiluminescence method | 0~2000x10-9 | 0.5x10-9 |

| ppbRAE3000 | TVOC | PID | 0~5000x10-6 | 1.0x10-9 |

| Gas chromatography-mass spectrometry linkage instrument | individual event MC | Chromatographic separation analysis | 0.5ug/m³ |

| SO2+H2S | NH3 | MC | |

| Average before installation | 9.6X10-9 | 114.8X10-9 | 2118.8ug/m³ |

| Average value after installation | 1.9X10-9 | 54.9X10-9 | 222.7ug/m³ |

| Final stable value | 1.9X10-9 | 25.1X10-9 | 67.7ug/m³ |

| rate of decline | 80.2% | 78.1% | 96.8% |

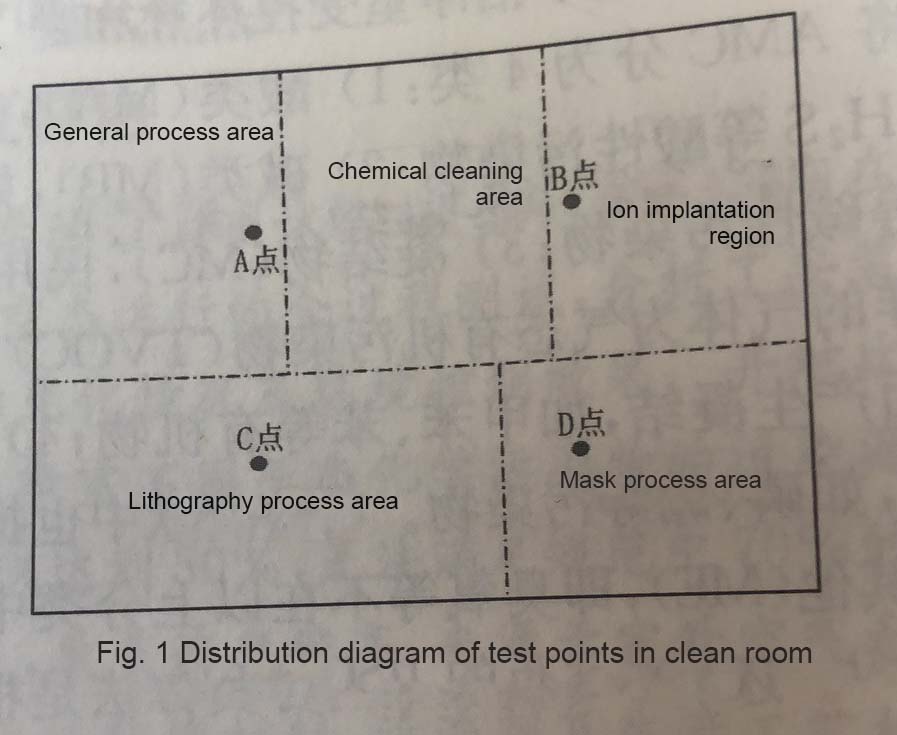

| Volume fraction of point A | Volume fraction of point B | |

| toluene | 1.69 | 0.5 |

| ethylbenzene | 2.43 | 2.09 |

| ortho-xylene | 3.10 | 2.26 |

| M-p-xylene | 8.56 | 6.90 |

| dichloromethane | 1.93 | 0.68 |

| Chloroform (chloroform) | 0.19 | 0.19 |

| benzene | 0.32 | 0.27 |

| 1,2- dichloroethane | 1.76 | 0.44 |

| 1,1,2- trichloroethane | 0.20 | 0.20 |

| tetrachloroethylene | 0.79 | 0.14 |

| styrene | 1.75 | 0.50 |

| trimethylbenzene | 0.64 | 0.48 |

| acetic acid | ethanol | Isopropyl alcohol | carbon tetrafluoride | Tetrafluoroethane | hexafluoroethane | |

| Volume fraction/10-9 | 18.2 | 184.7 | 71.4 | 2.4 | 37.3 | 92.3 |

Water source rooftop chiller unit part in HAVC

Water source rooftop chiller unit part in HAVC

The quietness and efficiency of Guqin series Horizontal Ultra-Thin Concealed fan coil units

The quietness and efficiency of Guqin series Horizontal Ultra-Thin Concealed fan coil units

Ultra-low temperature air source heat pump principle and core technology

Ultra-low temperature air source heat pump principle and core technology

Fan Coil Unit Selection And Product Advantages

Fan Coil Unit Selection And Product Advantages