Water source rooftop chiller unit part in HAVC

Water source rooftop chiller unit part in HAVC

The quietness and efficiency of Guqin series Horizontal Ultra-Thin Concealed fan coil units

The quietness and efficiency of Guqin series Horizontal Ultra-Thin Concealed fan coil units

Ultra-low temperature air source heat pump principle and core technology

Ultra-low temperature air source heat pump principle and core technology

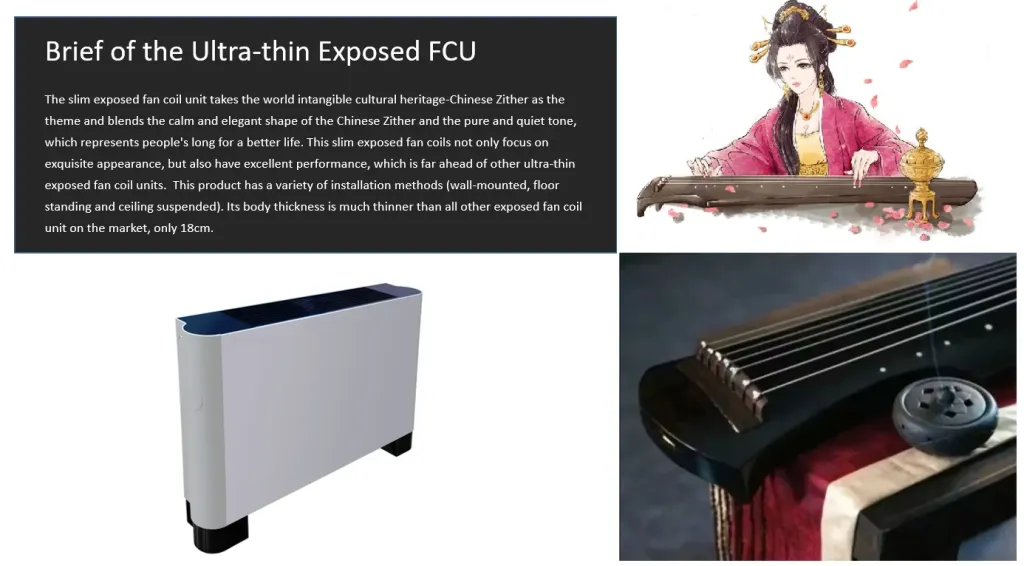

Fan Coil Unit Selection And Product Advantages

Fan Coil Unit Selection And Product Advantages